ZWell Grinding Balls for Ball Mill

Basic Information

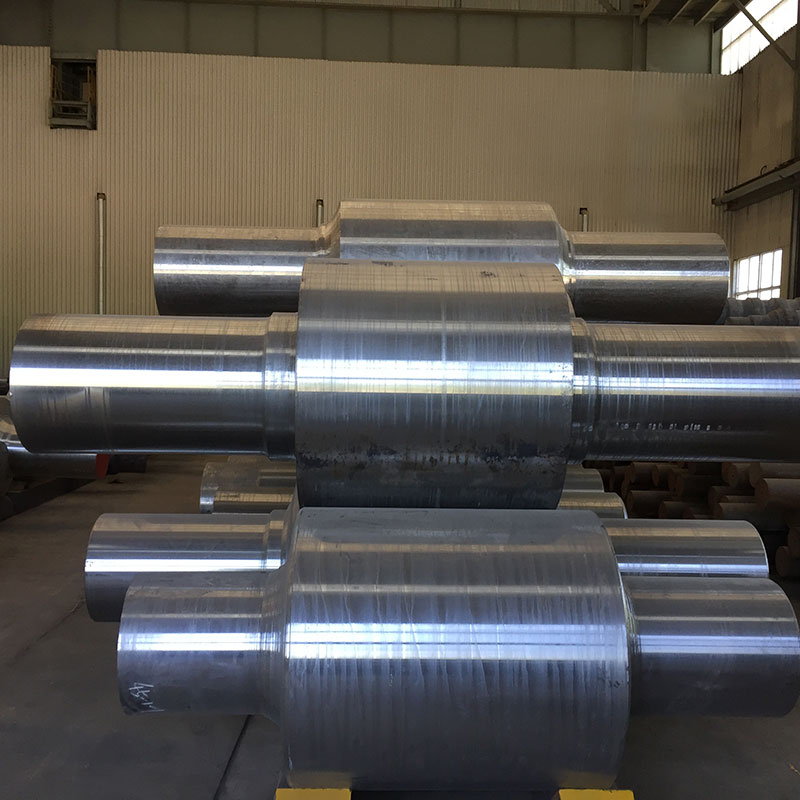

As a Jianlong Group grinding ball manufacturer, ZWell can produce and provide grinding steel balls for ball mills with annaul capacity of 100,000mts Ball grinding mill is the key equipment for grinding the material.

Ball mill is widely used in cement, silicate products, new building materials, refractory materials, chemical fertilizer, black and non-ferrous metal dressing and glass ceramics and other production industries.Ball mill can perform dry or wet grinding of various ores and other abrasive materials.

Ball mill is suitable for grinding all kinds of ore and other materials, and is widely used in mineral processing, building materials and chemical industries. According to the different ways of drainage, it can be divided into grid type and overflow type.

Ball mill is one of the widely used in industrial production, there are many kinds, Such as tube ball mill, rod ball mill, cement ball mill, ultrafine laminated mill, handball mill, horizontal ball mill, energy-saving ball mill, overflow type ball mill, ceramic ball mill, grid ball mill and so on.

ZWell can customize the ball mill using grinding steel balls and supply ball mill grinding schemes for clients from different industries.

Based on the achievements and experience of Jianglong Group’s R&D and production of steel, according to Jianlong Group’s own ore mining data and the various ball mills working condition, using advanced automatic steel ball production lines, and CNAS certified testing center, ZWell can customize the grinding steel balls suitable for various types of ball mills, helping clients save energy and improve production, reduce cost and increase efficiency.

For more information about ZWell Grinding Balls, please contact ZWell now.

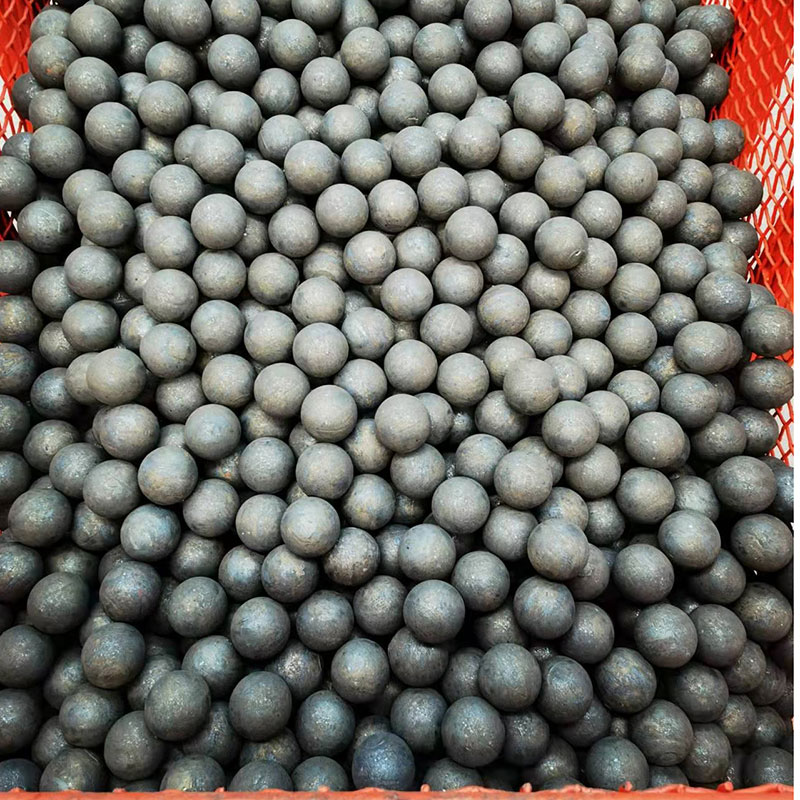

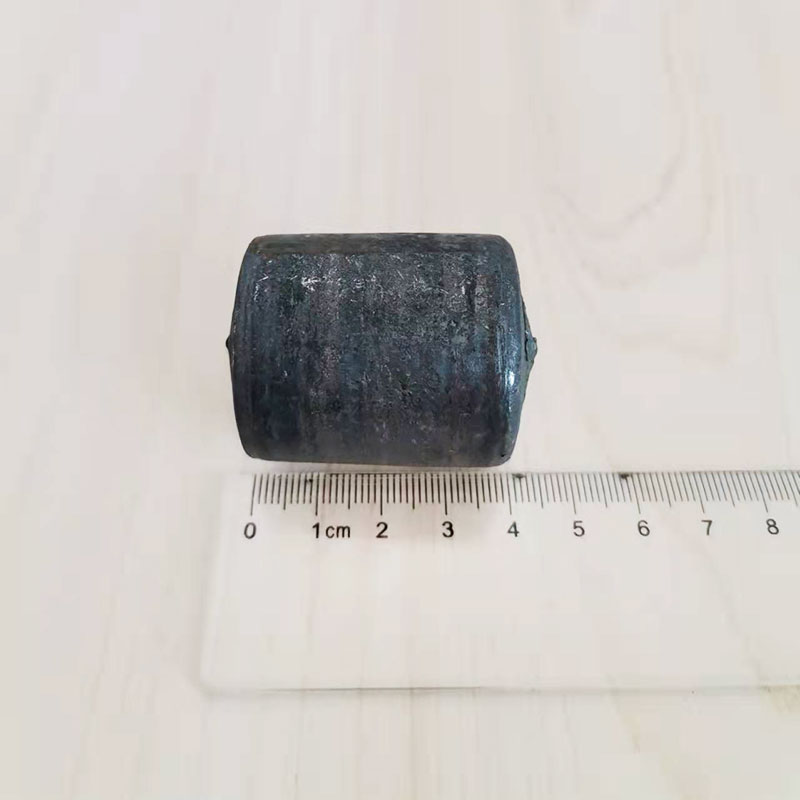

Product Features

- high and uniform hardness

- greater wear resistance and fatigue endurance

- smooth surface and low circle loss rate

- low breakage rate

Packing