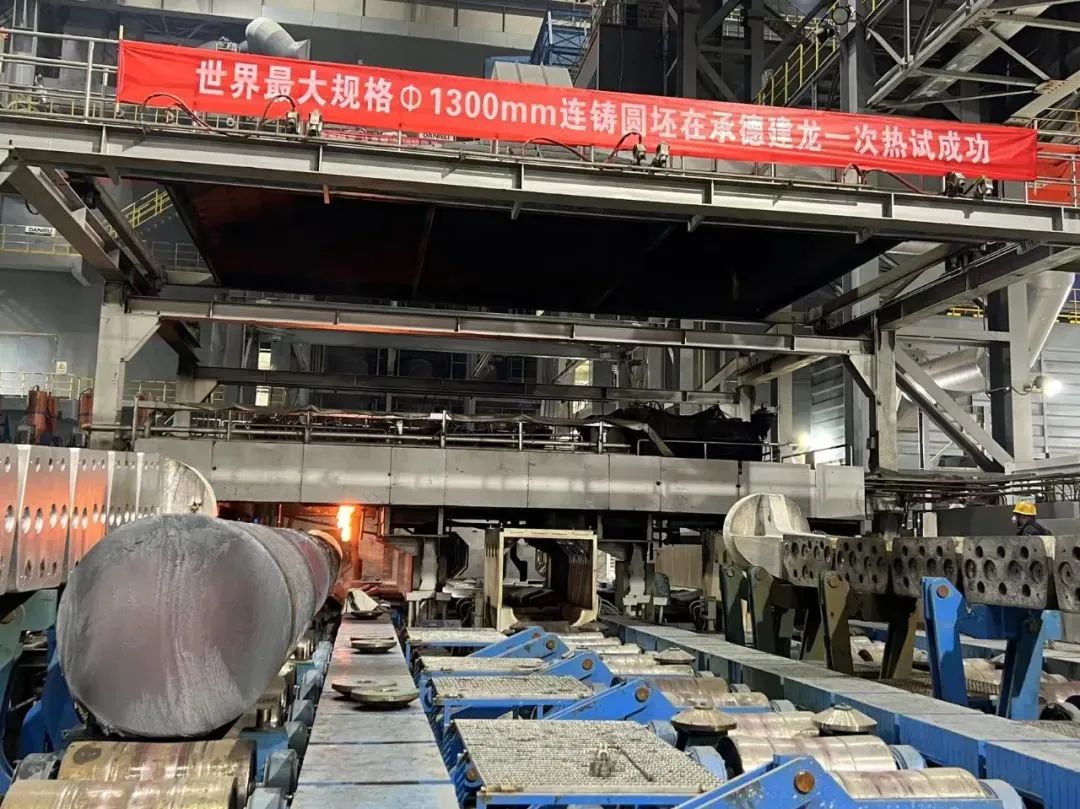

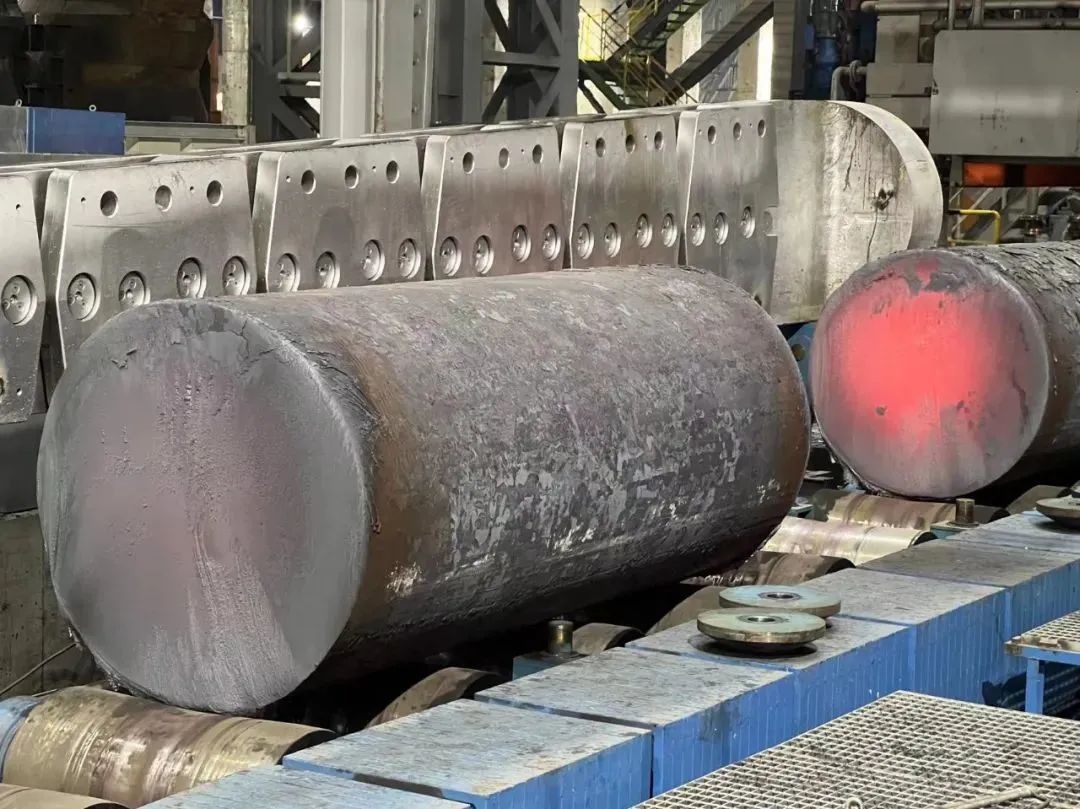

On January 30, the world’s largest Φ1300mm continuous casting billet was successfully hot-tested in Chengde Jianlong, which set a new record for the largest group distance of continuous casting billet in the world today and became the world leader.

This is also another major breakthrough of Jianlong Group in the production process and product development of high-end special steel, and an important reflection of the Group’s active response to the national call to promote the high-quality development of the industry and actively integrate into the global green low-carbon change industry chain.

Round billet products are mainly used for the new energy steel fields such as large offshore wind power and large-size oil service valve body. The birth of large-size continuous casting round billet will gradually rewrite the history of large thick-walled flanges using ingot forging, providing an important technology and equipment basis for the forging industry, the production of important high-end special steel materials and improvement of the metal yield, and providing important support for the development of China’s wind power and other clean energy fields.

The production line of oversized round billet continuous casting machine of Chengde Jianlong Vanadium and Titanium New Material was put into operation on August 27, 2022, which can produce large diameter continuous casting round billet of Φ700mm-Φ1300mm. Previously, Chengde Jianlong has successfully produced billets of Φ700mm, Φ800mm, Φ900mm and Φ1000mm. The line adopts unique electromagnetic stirring technology, intermediate ladle electromagnetic induction heating technology, fully automatic open pouring, vortex level automatic detection, Q-EMS (online dynamic electromagnetic stirring), Q-DTC (temperature control technology), LPC (solidification control model) and spraying robot and other processes and technologies, as well as additional auxiliary equipment and facilities such as annealing furnace and shot blasting machine, which is a world-class continuous casting line integrating environmental protection, advanced technology and intelligence.

In the future, Chengde Jianlong will continue to practice the concept of green manufacturing, increase scientific and technological innovation, and make steady progress towards the goal of building the most competitive global leader in energy-using steel.

Post time: Feb-02-2023