-

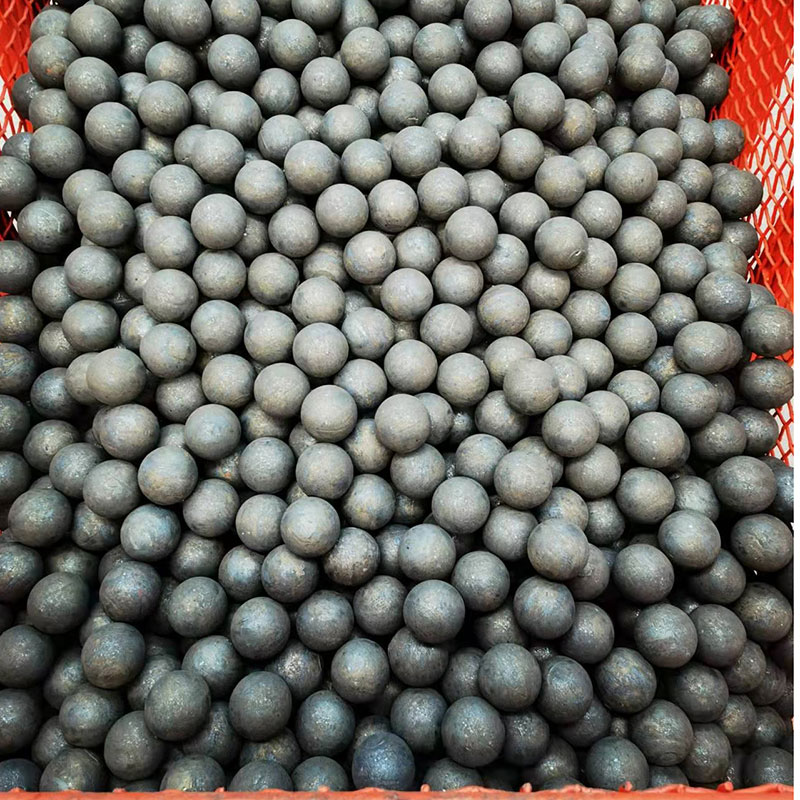

ZWell SAG Mill Grinding Balls

Mechanical Property

density:7.80-7.85g/cm³

surface hardness HRC:≥58

centre Hardness HRC:≥55

Ak:≥12J

ball test times:≥10000(10m)

as per standard:YB/T 091-2019 and order requirements -

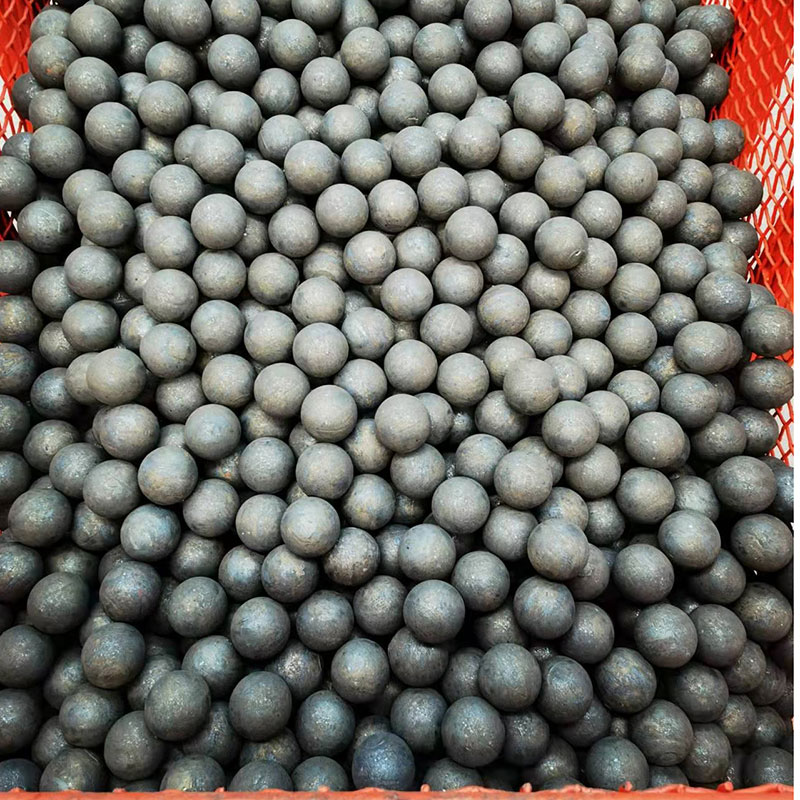

ZWell Grinding Balls for Ball Mill

Mechanical Property

density:7.80-7.85g/cm³

surface hardness HRC:≥60

centre Hardness HRC:≥57

Ak:≥12J

ball test times:≥10000(10m)

as per standard:YB/T 091-2019 and order requirementsAccording to the analysis of service condition of steel balls for large and medium-sized grinding mills at home and abroad, by using grinding steel Jianlong Beiman, the expert team developed wear-resistant steel producing process for the production of large diameter forged steel balls.

-

ZWQ Forged Steel Balls for Ball Mills

According to the analysis of service condition of steel balls for large and medium-sized grinding mills at home and abroad, by using grinding steel Jianlong Beiman, the expert team developed wear-resistant steel producing process for the production of large diameter forged steel balls.

-

zwq forged steel balls for sag mills

According to the analysis of service condition of steel balls for large and medium-sized grinding mills at home and abroad, by using grinding steel Jianlong Beiman, the expert team developed wear-resistant steel producing process for the production of large diameter forged steel balls.

-

ZWell Grinding Balls for SAG-Ball Mill Process

ZWell can produce and customize various diameter grinding ball for the SAG-Ball Mill grinding process.

The SAG (semi-autogenous grinding mill) is a grinding equipment with two functions: crushing and grinding. In addition to the crushed material itself as the grinding medium, large size steel ball is added. SAG mill can directly add large specifications of mineral particles.SAG mills have very wide application range, which expanded from the processing of non-metallic ore to ferrous metal, non-ferrous metal ore such as copper ore, molybdenum ore, lead and zinc ore and rare metal ore. -

ZWell Grinding Balls for Metal Ore Grinding

According to the analysis of service condition of steel balls for large and medium-sized grinding mills at home and abroad, by using grinding steel Jianlong Beiman, the expert team developed wear-resistant steel producing process for the production of large diameter forged steel balls.

-

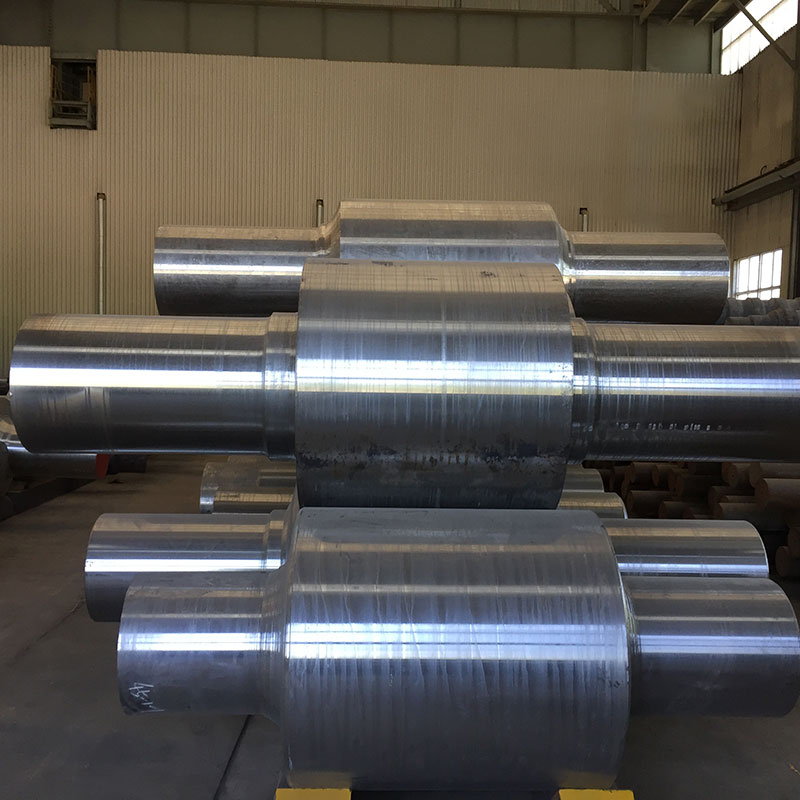

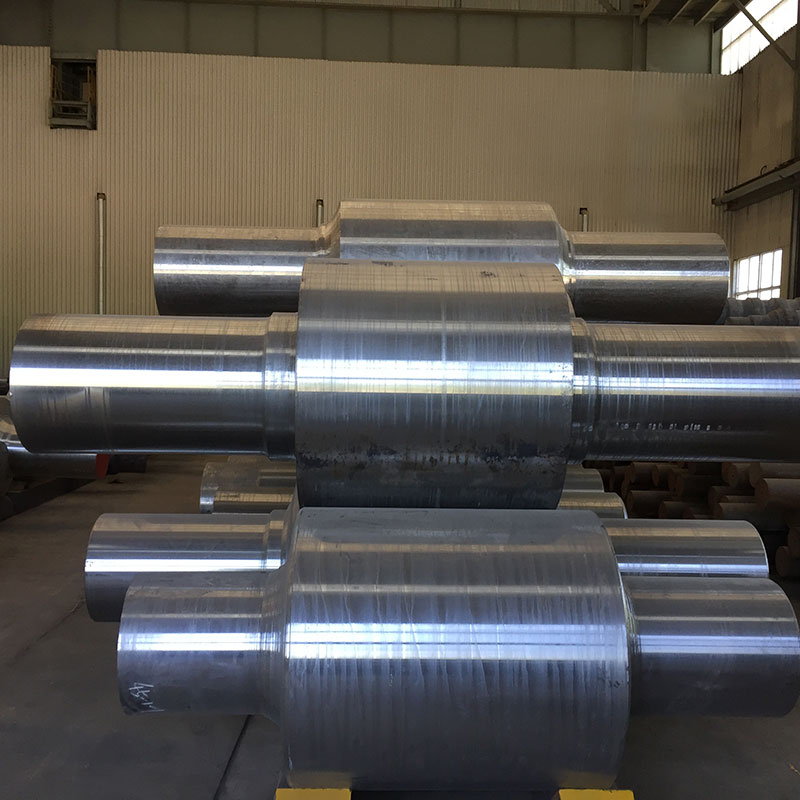

ZWell Forged Special Steel Forgings

ZWell main forged products include: forged steel grinding ball, forged die& mold steel, forged alloy structural steel and forged special steel forgings.The size range of forged steel round bar is 120-1200mm.The largest width of forged steel blocks can reach to 1550mm. Supply customized forgings according to drawings.

Contact ZWell to get the best price.

-

ZWELL Die&Mold Steel

• hot forged special steel blocks and round bars(hot work tool steel, plastic mold steel, etc. )

• annealed/normalized & tempered/quenched & tempered delivery condition

• black/milled/rough turned surface -

ZWB Grinding Steel Rod for Rod Mill

According to the analysis of service condition of steel grinding rods for rod mills in non-metallic mines, coal chemical industry and phosphorus chemical industry at home and abroad, the expert team developed Heat-treated steel grinding rods for rod mills

-

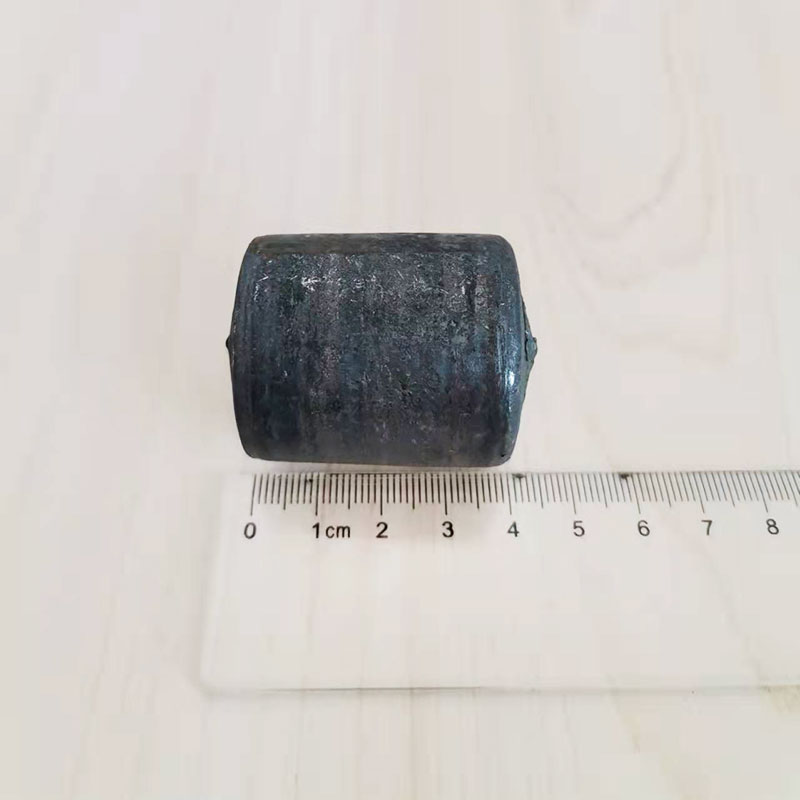

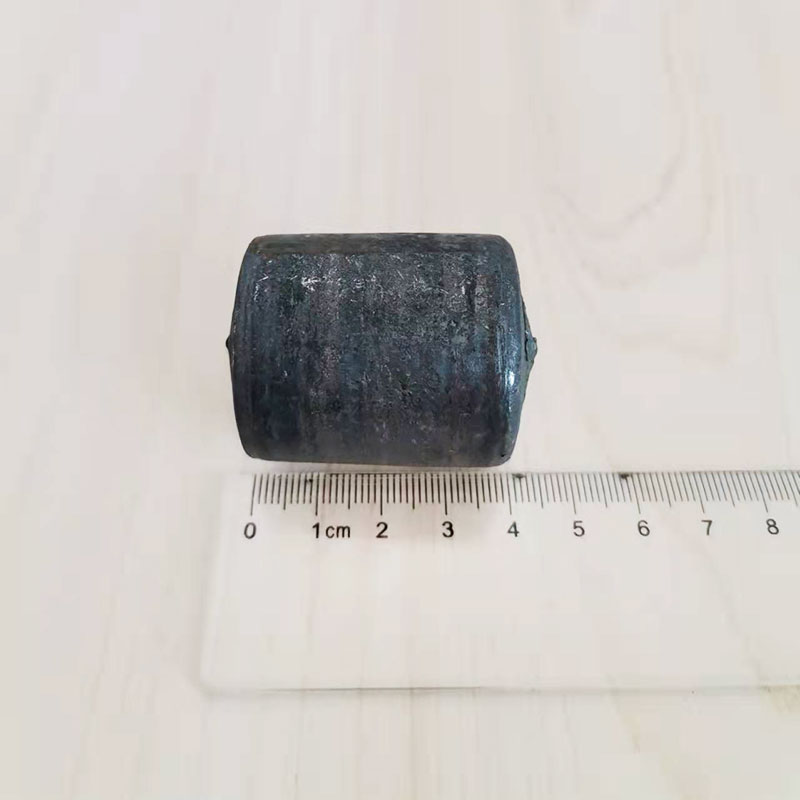

ZWD Forged Steel Cylpebs for Ball Mill

Mechanical Property

density:7.80-7.85g/cm³

surface hardness HRC:≥60

centre Hardness HRC:≥57

Ak:≥12J

ball test times:≥10000(10m)

as per standard:YB/T 091-2019 and order requirementsSelected patented(patent no.ZL 2017 1 0716046.7) new wear-resistant materials and intelligent control forging production line to make the cylpebs have uniuniform hardness, good toughness and cost-effective.