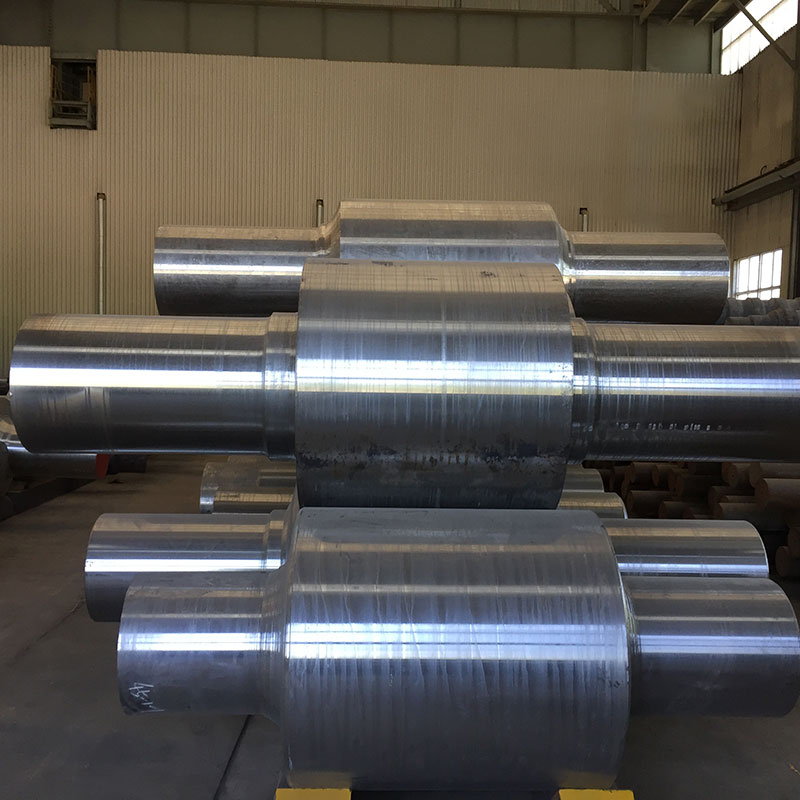

ZWB Grinding Steel Rod for Rod Mill

Basic Information

Tangshan ZWell Equipment Manufacturing Co., Ltd. is a Jianlong Group wholly-owned professional production base of grinding materials with annual capacity 100,000mts. Choose Jianlong Beiman high-quality steel as raw material, ZWell can provide high-quality steel grinding rods products for rod mill.

Steel grinding rod is a kind of grinding media filled in the rod mill. It is widely used in the grinding process of metallurgy, building materials, cement, mining and other fields. The steel grinding rods are thrown or slipped in the rotating rod mill. The ore in the mill is crushed by the moving steel grinding rods, so as to achieve the effect of grinding.

More information of size and grade, please contact ZWell.

Property Index

- Surface Hardness HRC:≥58

- Core Hardness HRC:≥55

- Impact Value Ak:≥12J/㎝²

Product Features

The intelligent production lines ensure the straightness, hardness, toughness and tensile strength of the bars which can meet the application of different types of rod mills. High strength, high wear resistant, no peeling and no deformation.

Size And Tolerance

| Diameter(mm) | Length(mm) | Diameter Tolerance(mm) | Length Tolerance(mm) |

| Φ50-150 | 2000-6000 | -1.6-0.2 | -20-0 |

Chemical Composition

| Grade | C(%) | Si(%) | Mn(%) | Cr(%) | Cu(%) | Mo(%) | P(%) | S(%) | Ni(%) |

| 45# | 0.42-0.50 | 0.17-0.37 | 0.5-0.80 | 0-0.25 | 0-0.25 | 0-0.30 | 0-0.035 | 0-0.035 | 0-0.30 |

| 60Mn | 0.57-0.65 | 0.17-0.37 | 0.70-1.0 | 0-0.25 | 0-0.25 | 0-0.30 | 0-0.035 | 0-0.035 | 0-0.30 |

| 65Mn | 0.62-0.70 | 0.17-0.37 | 0.90-1.0 | 0-0.25 | 0-0.25 | 0-0.30 | 0-0.035 | 0-0.035 | 0-0.30 |

| 40Cr | 0.37-0.45 | 0.17-0.37 | 0.50-0.8 | 0.80-1.1 | 0-0.25 | 0-0.30 | 0-0.035 | 0-0.035 | 0-0.30 |

| 42CrMo | 0.38-0.45 | 0.17-0.37 | 0.50-0.80 | 0.90-1.2 | 0-0.03 | 0.15-0.25 | 0-0.035 | 0-0.035 | 0-0.30 |

| ZWB-2 | 0.70-0.80 | 0.17-0.37 | 0.70-0.80 | 0.50-0.60 | 0-0.25 | 0-0.30 | 0-0.035 | 0-0.035 | 0-0.30 |

Technical Specification

| Impact Value(J/㎝²) | Hardness(HRC) | Breakage Rate | Drop Times | Straightness | |

| 5-7 | 45-55 | < 1% | ≥ 30 | 2/1000 | |